Yamaha CLP-370 with Sticking, Clunking, and Dead Keys

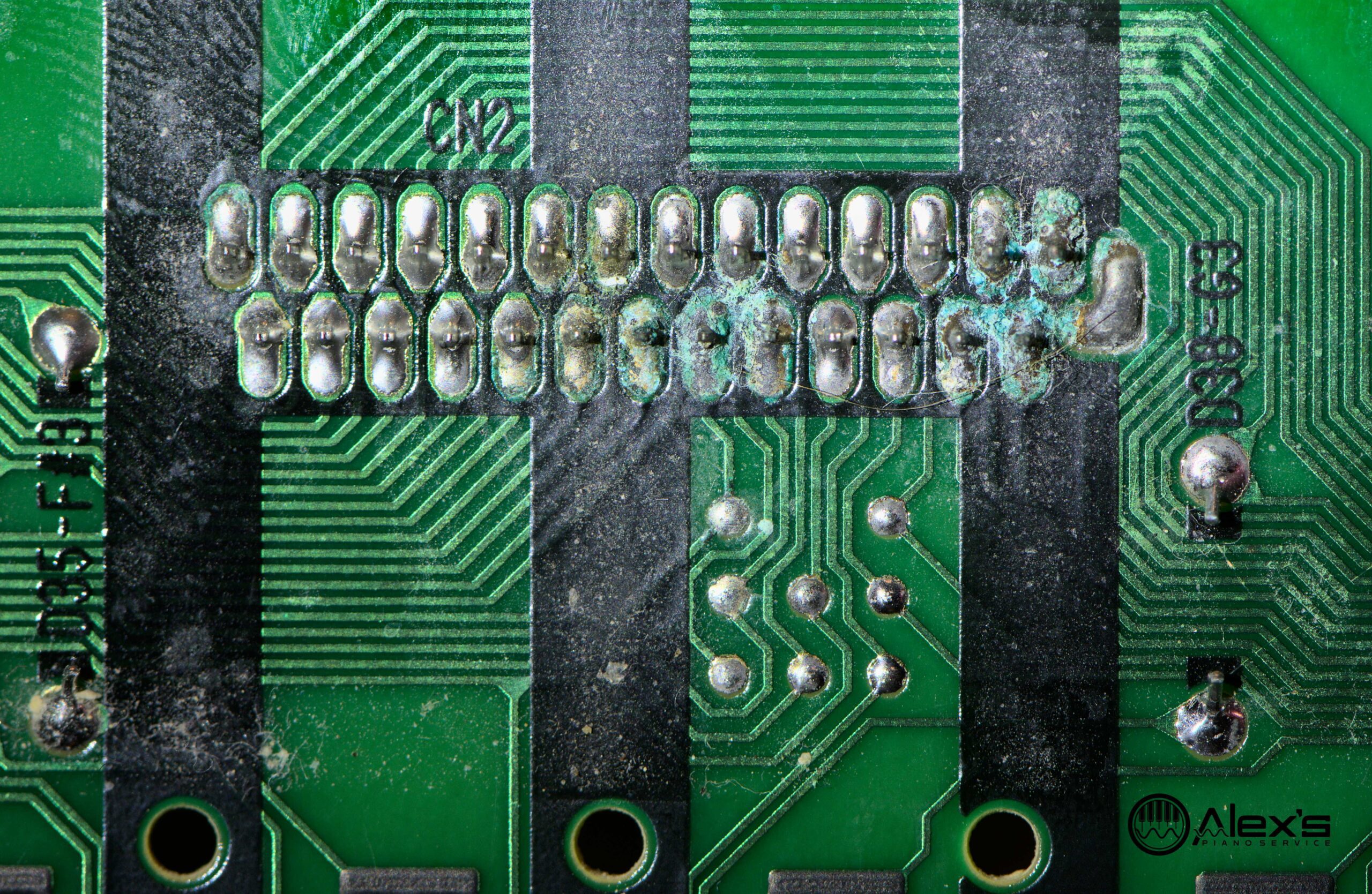

Today I’m sharing a few pictures of a repair on a Yamaha CLP-370 with sticking keys, clunking sounds, and dead keys. But this could happen on most Yamaha Clavinovas. See my Digital Keyboard FAQ for more! Hammer Rest Felt (Sticking and Clunking) One of the most common complaints I receive from customers is that their … Read more